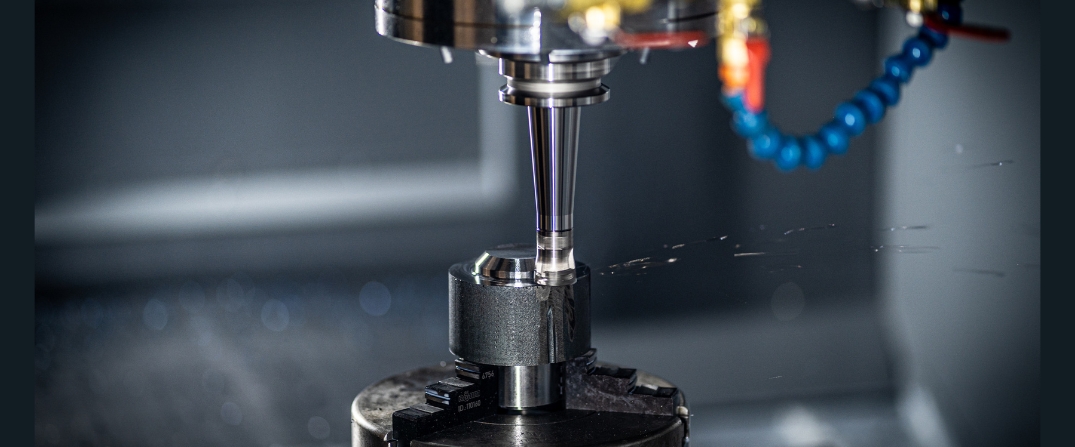

In today’s fast-paced manufacturing landscape, efficiency and traceability are key to staying competitive.

GITS recently partnered with a subsidiary of a leading Japanese Heavy Industry Group to develop a robust Production Management System that seamlessly integrates various processes, enhances traceability, and ensures operational excellence. Here’s how we did it.

Understanding the client’s challenges

The client, strategically based in Hanoi, Vietnam, faced significant challenges in managing its production workflow.

With operations spanning procurement, warehousing, processing, assembly, and quality control, the client needed a centralized system to manage its entire production flow.

The system had to ensure end-to-end product traceability, integrate seamlessly with external systems such as PLC, ERP, and barcode tools, and improve overall operational efficiency and data accuracy.

Without an advanced Production Management System, the company risked inefficiencies, data silos, and compliance issues.

Our tailored IT solution

To address these challenges, GITS devised a two-phase approach:

Phase 1: Business analysis & specification definition

Our Business Analysts conducted a deep dive into the client’s production workflow. We carefully analyzed which processes should be automated through software and which should remain manual or integrate with existing systems. The outcome was a clear software specification and system architecture roadmap.

Phase 2: Development

With the blueprint in place, our development team built and deployed a custom Production Management System, featuring:

- End-to-end workflow automation from procurement to final production

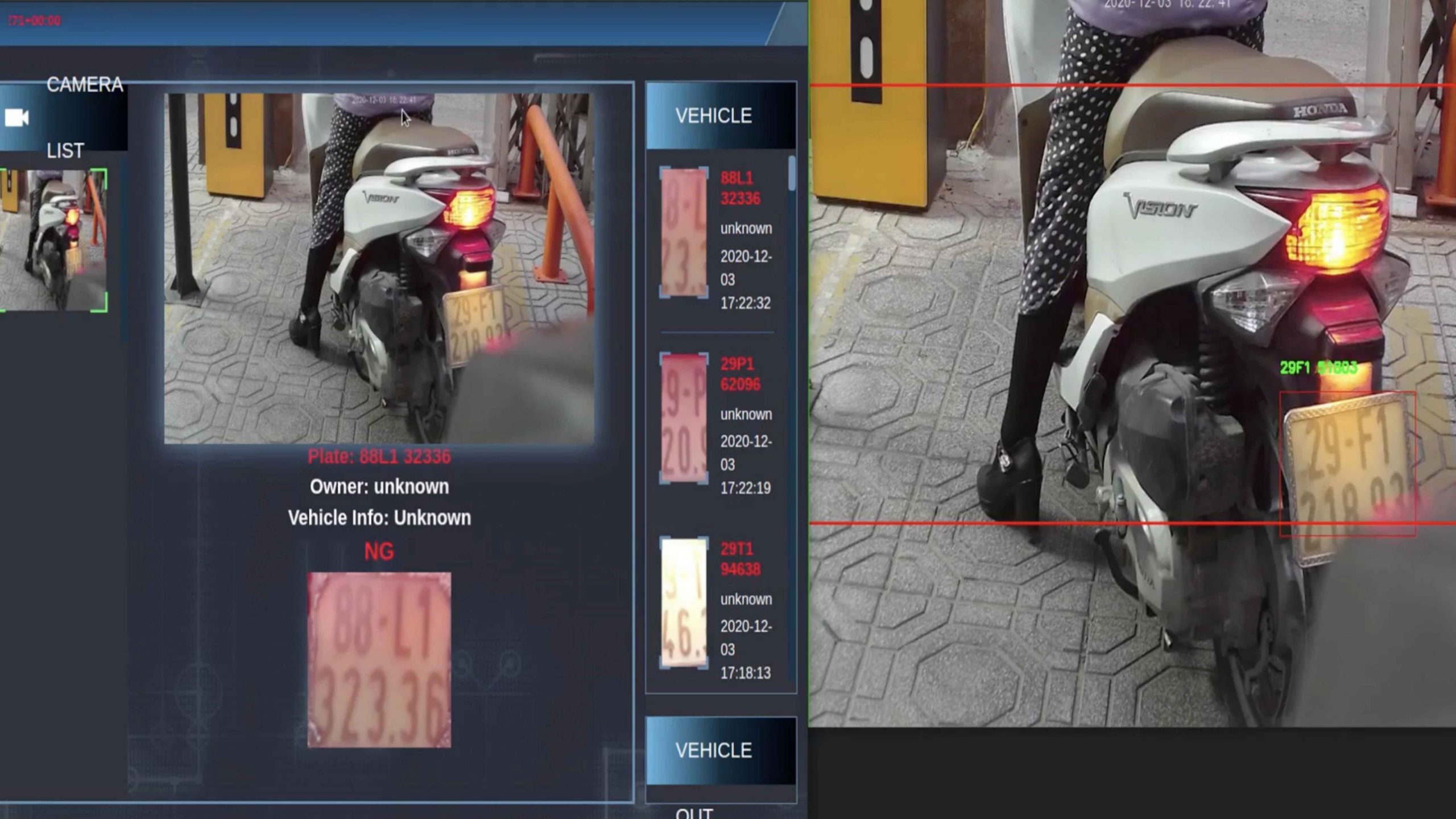

- Seamless barcode and QR code integration for accurate product traceability

- ERP and PLC system integration for real-time data synchronization

- Robust user and inventory management to streamline operations

- Custom reporting and analytics for valuable business insights

GITS worked closely with the client’s IT department to ensure a smooth go-live process, minimizing downtime and ensuring user adoption.

Key features of the production management system

Our custom-built system consolidates all key production functions into a single Front-End Application. This includes real-time production line monitoring, purchasing and sales management, assembly and quality control, stock and inventory management, QR code generation and scanning, and production planning with reporting for data-driven decision-making.

All data is securely stored in a centralized database with an advanced Data Access Layer, enabling seamless communication between internal modules and external ERP systems.

Technology stack

To build a future-proof and scalable solution, GITS leveraged the latest technologies. The mobile application is Android-based for on-the-go access. Cloud and web technologies include Java Spring Boot and React JS for high performance and flexibility. This modern tech stack ensures fast, secure, and efficient operations, making the system adaptable to evolving business needs.

Measurable business benefits

The results of our collaboration were transformational for the client. The production cycle became 50 percent faster through automation and workflow optimization. The accuracy in inventory tracking reached 99 percent with barcode and QR code scanning. Seamless ERP integration reduced manual data entry errors by 80 percent. Real-time data analytics led to more informed business decisions. Improved compliance and traceability ensured better quality control.

With a unified system in place, the client now enjoys enhanced efficiency, reduced costs, and improved product traceability, which is a true game-changer in manufacturing.

Transform your manufacturing operations with GITS

If you are looking to optimize your production process, enhance traceability, and integrate seamlessly with ERP systems, GITS has the expertise to make it happen.

Contact us today to discuss how we can tailor a solution to your business needs. Contact us today to learn more about our IT solutions for manufacturing.