Introduction

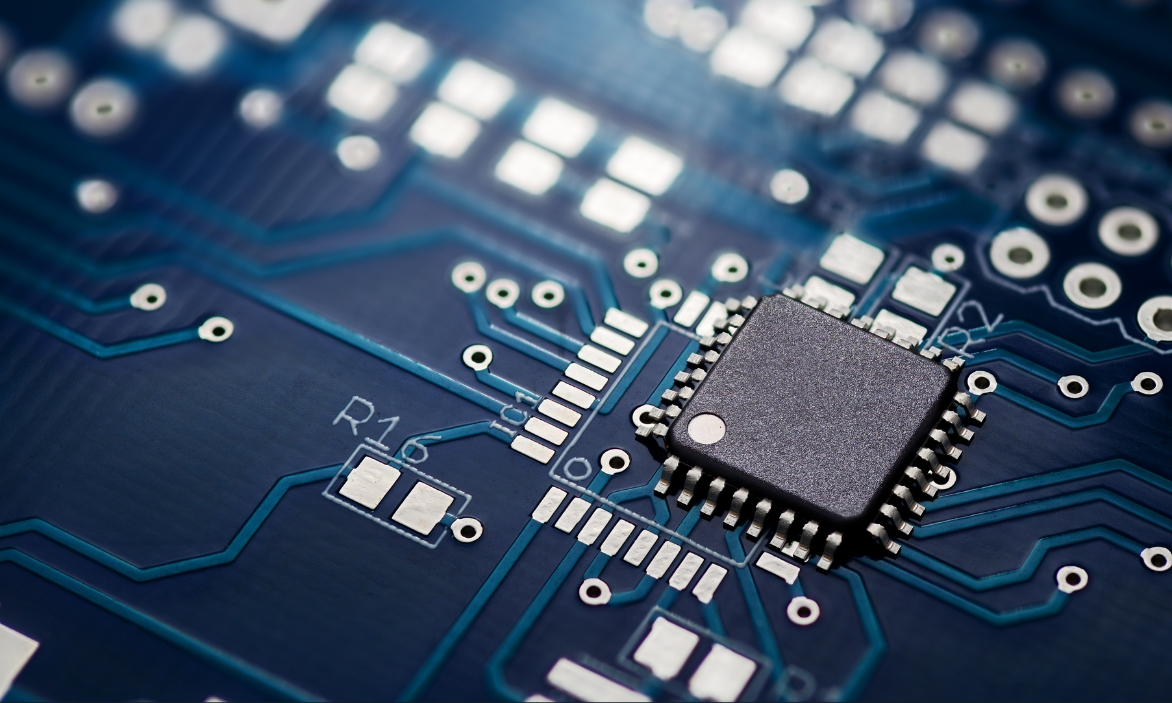

Precision and quality control are crucial in industries such as smart devices, automotive electronics, telecommunications, healthcare, and semiconductors. A leading Korean provider of measurement-based inspection equipment sought to enhance their PCB (Printed Circuit Board) quality inspection process with a modernized, real-time monitoring system.

By partnering with GITS, they successfully implemented a Product Quality Inspection & Monitoring System that leverages high-resolution imaging, data analytics, and web-based visualization. This transformation improved production efficiency, defect detection, and decision-making, setting a new benchmark for quality control in PCB manufacturing.

Customer overview

The client specializes in measurement-based inspection solutions, ensuring high precision in quality control and process optimization across multiple industries. They required an intelligent software solution that could:

– Capture high-resolution images of PCBs during production.

– Analyze defects and highlight quality issues in real-time.

– Provide visualized monitoring data to factory managers.

The goal was to enhance production efficiency by quickly identifying and addressing defects, ensuring the highest standards of quality.

Our solution: a two-part advanced inspection system

To meet the client’s demands, GITS designed and implemented a comprehensive quality inspection system with two core components:

1. Desktop application for inspection machines

– The system integrates with PCB inspection machines that capture high resolution images.

– The software analyzes the images, identifying defects, misalignments, and inconsistencies in real-time.

– The analyzed data is transmitted to a central server, enabling factory-wide monitoring and reporting.

– The results are displayed on-screen, providing engineers with instant feedback for corrective actions.

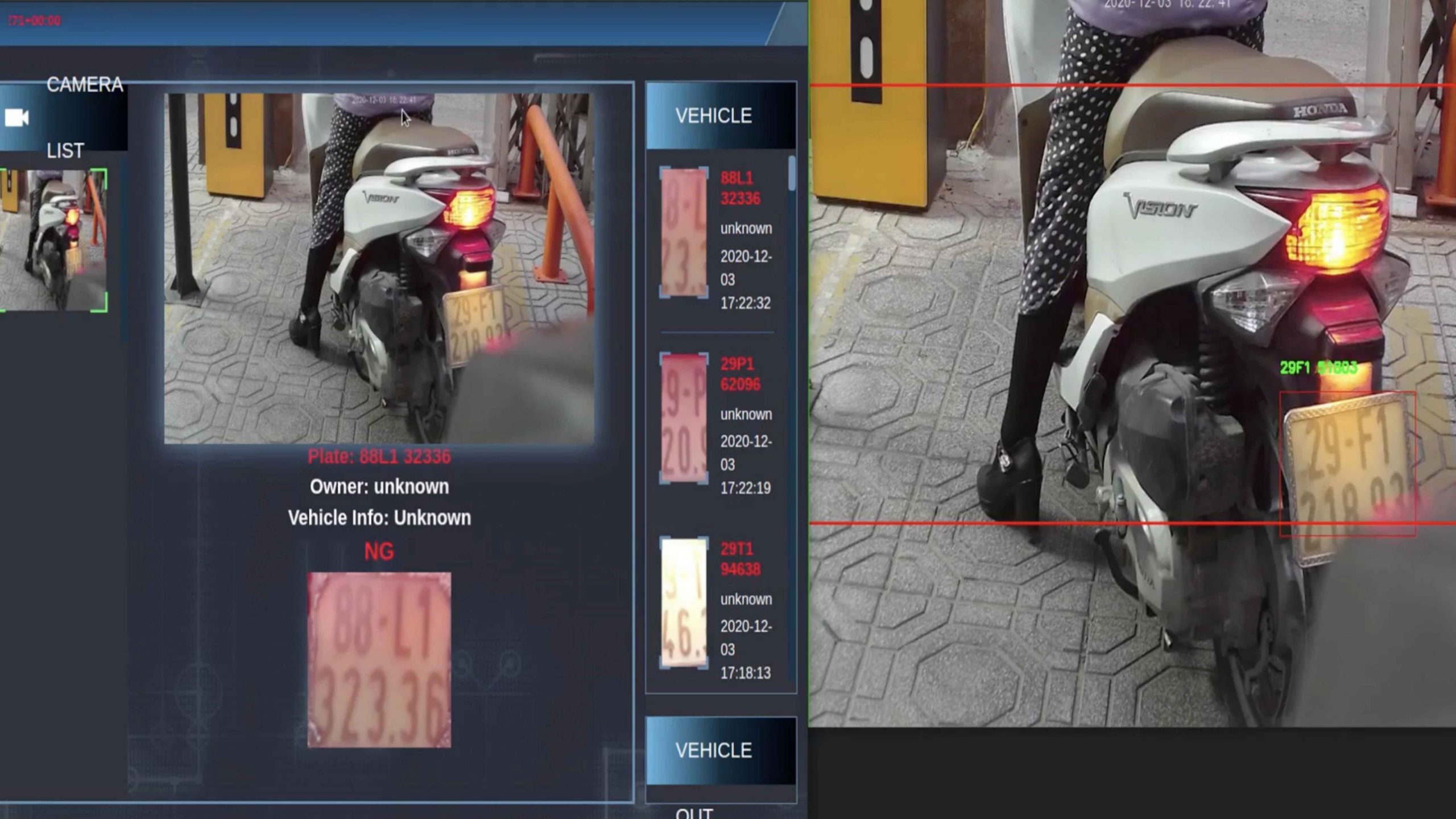

2. Web-based monitoring system for real-time visualization

– The monitoring system is developed as a web application, accessible from any device (PCs, tablets, and mobile phones).

– It provides a clear, visual representation of quality data across all production lines.

– Factory managers can track defects, analyze trends, and optimize production processes based on real-time data.

– The system supports data-driven decision-making, allowing engineers to improve manufacturing efficiency.

Collaboration & on-site support

To maximize efficiency and minimize costs, we deployed a dedicated development team to work onsite with the customer’s engineers. This ensured seamless integration, continuous support, and optimized maintenance costs.

Technology stack and system architecture

The system was built using a robust and scalable tech stack:

– Desktop Application (running on PCB inspection machines): Developed using C#, WPF, and C/C++, ensuring high performance and real-time image processing.

– Monitoring Web Application: Built with Java Spring Boot (backend), Oracle (database), and Angular (frontend) for a modern, user-friendly dashboard.

The architecture enables seamless communication between inspection machines and the monitoring system, ensuring accurate and fast defect detection.

Project impact: enhanced quality control & efficiency

The implementation of this system transformed the client’s PCB inspection process, leading to several key benefits:

– Improved defect detection: High-resolution imaging and automated analysis allowed for faster identification of PCB defects.

– Real-time monitoring: Factory managers gained instant access to quality insights, enabling quicker corrective actions.

– Optimized production efficiency: Engineers could fine-tune production lines based on accurate defect data.

– Reduced operational costs: The web-based system eliminated manual reporting, saving time and reducing human error.

The successful deployment of this cutting-edge inspection and monitoring system has significantly enhanced product quality, ensuring the client maintains its leadership in precision inspection solutions.

Project details

– Development team: 15 members.

– Project duration: 12 months.

– Responsibilities: Detailed design, programming, integration testing, and operational support.

Conclusion

By implementing an AI-driven, real-time monitoring system, GITS empowered a global leader in PCB inspection to enhance quality control and production efficiency. With this success, the client now benefits from faster defect detection, automated reporting, and smarter decision-making—setting new standards for high-precision manufacturing.

If your business is looking for a customized quality inspection solution, contact GITS today to discuss how we can help you revolutionize your production process!